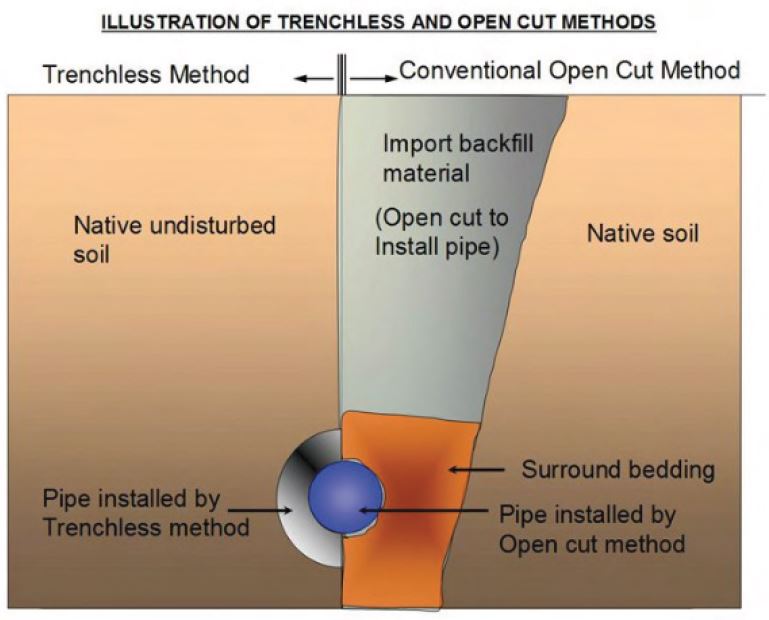

Developed in the 1970’s, trenchless (no-dig) technology involves innovative methods, materials, and equipment used for the installation of new and the rehabilitation or replacement of existing underground infrastructure with minimal or no need for open cut excavation.

Cost Savings

Traditional “dig and replace” methods include costs for labor, the displacement of earth, and many hours spent restoring or replacing the structure. No-dig technology is a more cost-effective method of replacing deteriorating structures without digging, which provides significant cost-savings to municipalities and ratepayers alike.

Time-Savings

Because no-dig makes use of the existing structure, extensive excavation is no longer needed, which drastically shortens the length of the process.

Obviously, decreasing project time and materials make a rehabilitation cheaper than replacing with a new one. It’s also possible to eliminate the costs and risk of possibly contaminated soil and debris removal and disposal caused by digging up an old manhole structure. One final benefit of no-dig is that by avoiding the need for excavation, streets can be kept open and functioning while work progresses, which is a win-win for everyone. So overall, no-dig eliminates paving, reduces traffic interruptions, minimizes community disruption, and provides a quick return to service.

Risk Mitigation

This proven technology is an environmentally-sound alternative for infrastructure rehabilitation as it will not require heavy or loud equipment and the risk for potential air and water pollution is mitigated. For the same reason, there is a reduced carbon footprint. It is said that dig-and-replace projects consume up to 50 times more energy than no-dig methods, so with fewer CO2 emissions, there are less greenhouse gases.

In addition, one often overlooked but very important benefit of no-dig technology is the reduction of health and safety risks for workers.

D.A.T is a program Infrastruct developed from exploring manhole renewal technologies, researching studies and design practices across the world. The D.A.T. program takes an exploratory understanding of the source of the problem, defines the needs, and seeks the proper treatment. Some rehabilitation techniques are also applied outside the context of rehabilitation, particularly, in maintenance activities or for preventive purposes(e.g. material protection in order to avoid the posterior degradation), usually repair or renovation techniques.

Step 1

A diagnosis of the problem needs to be defined. Understanding the behavior we are trying to resolve. Three behaviors:

Step 2

Selection of the appropriate behavior leads to advise; do we repair, renovate or replace? In the following sections, each family of techniques is briefly described including an overview of the main characteristics, conditions of application, advantages and disadvantages, and relevant standards.

Step 3

Treat means to select the right technology, the right trade or applicator (private or public) with the history and skills required to complete the project safely, on time and on budget.